You’ve got a solid safety program. Annual training is checked off. Protocols are documented. Your completion rates look decent on paper.

Then winter hits, and everything quietly breaks. Injuries spike, protocols get skipped, and the training you invested in doesn’t seem to stick when it matters most. Winter adds hazards and breaks the systems you already have in place.

Let’s talk about why that happens and what actually works to fix it.

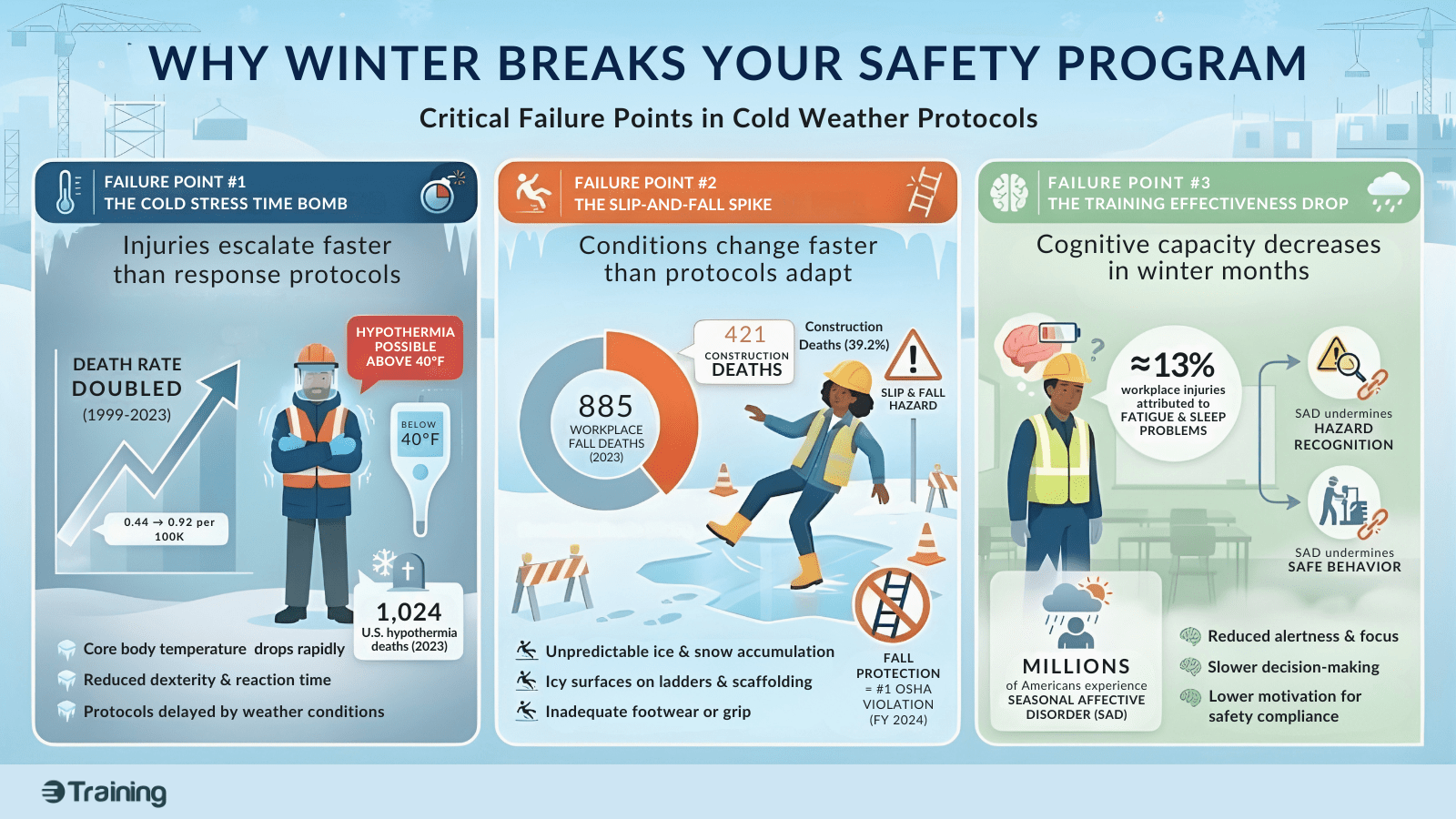

Cold stress injuries escalate faster than most response protocols can handle. In 2023, 1,024 people in the U.S. died from hypothermia or extreme cold, and the death rate has more than doubled since 1999, rising from 0.44 to 0.92 per 100,000 people. Between 1999 and 2022, over 40,000 Americans lost their lives to cold exposure, with the sharpest increases occurring after 2017.

Hypothermia can occur at temperatures above 40°F if workers become chilled from rain, sweat, or cold water exposure. OSHA’s guidance shows that frostbite risk increases exponentially with wind chill, yet most programs treat cold stress like heat stress with the temperature scale flipped.

The physiology is different. When your body shifts blood flow from extremities to protect core temperature, frostbite can set in within minutes under the right conditions. By the time visible symptoms appear (gray/white skin patches, numbness), tissue damage has already started. CDC/NIOSH emphasizes that cold stress can affect any worker exposed to cold environments, and even well-trained military personnel aren’t immune. The U.S. Armed Forces diagnosed 456 service members with cold injuries in the 2023-2024 winter season alone.

Most cold stress training covers the symptoms. What it doesn’t cover: how fast things go sideways once a worker is wet, tired, or working alone in windy conditions. The gap between “I’m cold” and “I need medical attention” can be 15 minutes, not the 45 minutes your incident response protocol was built around.

The disconnect: Your standard “watch for warning signs” approach assumes you’ve got time to respond. Training says “take breaks in warm areas.” Reality: your crew is on a remote jobsite with a diesel truck cab that takes 20 minutes to heat up, or in a warehouse where the “warm area” is 55°F. The protocol doesn’t match the environment, so it gets ignored.

Winter slip-and-fall incidents are frequent, expensive, and predictable. The numbers from the Bureau of Labor Statistics (BLS) tell the story:

That space between the heated building and the parking lot. The loading dock after a morning freeze-thaw cycle. The sidewalk where yesterday’s snowmelt refroze overnight into black ice. These are mundane, constantly shifting conditions that standard fall protection training programs don’t address because they change by the hour. And employers are paying for it. Fall Protection remained the most cited OSHA violation in 2024 for the fourteenth straight year across all industries.

The training gap: Most slip-and-fall training shows workers how to identify hazards. But winter hazards don’t exist until suddenly they do. A walkway that was safe at 7 a.m. is a skating rink by 8:30 a.m. after the sun hit that patch of compacted snow. Workers get trained once in October, then face changing conditions daily for four months.

Standard programs treat surface management as a facilities issue and personal awareness as a training issue. They’re both operational issues that require constant adaptation, and most safety programs aren’t built for that level of ongoing response.

Your training completion rates drop, comprehension suffers, and retention falls off in winter. Not because your training got worse. Because your workers’ capacity to engage with it decreased.

According to the National Safety Council (NSC), ≈ 13% of workplace injuries can be attributed to fatigue and sleep problems, which often increase during winter due to shorter daylight hours and seasonal disruptions in sleep.

Millions of Americans experience Seasonal Affective Disorder (SAD), with significantly higher rates in northern climates like Alaska and New England. SAD symptoms include low energy, difficulty concentrating, and changes in sleep and appetite, all of which impact a worker’s ability to absorb and retain safety training. And yet most safety training programs schedule the same 45-minute PowerPoint sessions in January that they ran in July, expecting the same results. Add shorter daylight (which reduces in-person training opportunities), cold-induced fatigue, and the cognitive load of the holiday season, and you’re asking workers to absorb critical safety information under the worst possible conditions.

The reality: If you’re seeing 30% training completion rates industry-wide, what do you think that number drops to when workers are:

The training that doesn’t land in October definitely won’t land in January. But most programs keep delivering it the same way, then wonder why incident rates climb.

Most safety programs treat winter as an add-on. A supplemental module on cold stress. A reminder email about icy walkways. An extra section in the toolbox talk.

Your training delivery needs to adapt for seasonal attention spans and cognitive load. Your incident response times need to account for how fast cold stress escalates. Your surface management can’t be a “salt the walkways” checkbox, it needs to be a dynamic, hourly assessment process during freeze-thaw cycles.

Winter is an operational risk period that requires different protocols, adapted training delivery methods, and response procedures built for the actual timeline of winter injuries. The safety programs that work in winter are the ones that asked: “How do we need to operate differently when temperatures drop, daylight shrinks, and our workforce is dealing with seasonal cognitive challenges?”

Most programs never ask these questions. They add content but don’t change the system. And every winter, the same predictable failures repeat.

Here’s what actually closes the winter safety gap:

For cold stress: Monitoring protocols that account for wind chill and wet conditions, work/rest cycles that adjust based on actual conditions (not just temperature), and response procedures built for how fast things escalate. Plus training that’s accessible when workers need it (mobile-first, short modules they can complete during weather delays instead of requiring everyone in a freezing conference room).

For slip-and-fall prevention: Surface treatment schedules that respond to changing conditions throughout the day, footwear standards that match actual winter environments, and housekeeping protocols specifically for transition zones where ice forms unpredictably.

For training effectiveness: Timing adjustments that account for daylight and cognitive load, session length modifications for seasonal attention spans, and engagement tactics specifically designed for workers dealing with winter conditions. Interactive, scenario-based training that workers can complete in 10-15 minute segments on mobile devices, not 60-minute sessions that assume focus and comfort.

Failing programs treat winter as additional content to deliver. Adaptive programs treat winter as a different operating environment that requires different systems.

If your winter safety approach looks like your summer approach with a cold stress module attached, you’ve got gaps. The question is whether you’ll close them before the next freeze or after the next preventable injury.

Ready to close those gaps? Our Winter Workplace Safety Readiness Audit walks you through the exact system checkpoints that adaptive programs use. It’ll take you 10 minutes to identify where your winter protocols are solid and where they’re quietly failing.

Sources:

We build interactive safety training that’s designed for how people actually learn. Our courses are mobile-accessible, scenario-based, and structured for the real conditions your workers face, including winter. Average completion rate of our courses is 87%, compared to the industry standard of 30%. Because training only works if people actually finish it and remember what they learned.

No Minimums. No Contracts. Set it up in minutes and start assigning courses right away.